Quite simply, a SCADA is a software application that is used to manage the automation of a process or system. Its primary functions include data acquisition, alarm management, and scalability. It is a solution that can be used in a variety of industries, including manufacturing, mining, and energy.

Data acquisition

Managing the process of data acquisition is important for a company’s success. Data is the basic resource for decision making and planning. There are a number of options available for data acquisition including networked data communication, sensors, PLC/RTU, and PC based data acquisition software.

There are many factors to consider when choosing the right type of data acquisition software for your business. It is important to choose a system that will work best with your existing processes and infrastructure.

There are a number of specialized data acquisition software options available for SCADA systems. Some of these programs can convert data into a variety of formats.

Data acquisition software includes a wide range of applications, from simple measurement and control programs to more complex industrial control software. You can even have a custom designed program created to perform specific functions.

Data acquisition software is designed to collect and store information about a variety of digital devices. This includes PLC/RTU data, production data, fault history, and process variable trends.

A PC based SCADA system offers a centralized data collection point, enabling users to quickly access production data. This system also provides a secure way to view and analyze production data.

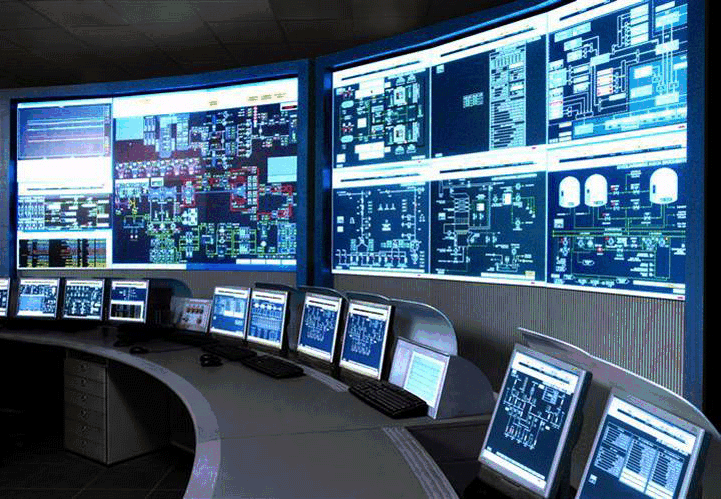

A human machine interface (HMI) device provides an interactive user interface, allowing operators to interact with and modify the data. This device also acts as a central processor. It can be used to filter data and create reports for remote data acquisition applications.

A master/slave system is a type of SCADA configuration that allows complete control of communications. This allows data to be distributed only when a significant change is detected. It is one of the most popular systems for acquiring data.

Networked data communication

Generally, SCADA is used in industrial processes and helps in enhancing efficiency and reducing waste. In addition, SCADA offers insights into the wider industrial processes.

The main purpose of SCADA is to monitor and control the operations of industrial processes. SCADA also provides increased flexibility and scalability. It allows the organization to connect more devices to the SCADA network. Moreover, it ensures timely handling of events.

The SCADA system can be implemented with a variety of hardware and software. The software primarily consists of graphical user interfaces (HMIs). These HMIs display information in a way that is actionable. The software also logs events into a hard disk. The system also has the ability to sound alarms.

In addition, the SCADA system can control actuators. These actuators are used to control the industrial processes. Typically, they are configured like switches or dials. The data from these field devices is transmitted to SCADA supervisory computers. These computers then send control commands to the actuators.

In addition to the above-mentioned components, SCADA systems also have the ability to connect to other similar systems. These systems usually have significant redundancy built into their architecture.

Another important feature of SCADA is that it provides a graphical user interface (HMI). The HMI typically displays information in a way that is easy to understand and interpret. It also has the ability to provide trend graphs and alarms.

Another important feature of SCADA is the security of the network. SCADA security is an issue that is becoming more important. Private companies, government agencies, and utilities must make sure that SCADA security is in place.

Modern SCADA systems are supported by open networking standards. They do not rely on proprietary software or communication protocols. They use commercial off-the-shye hardware.

Alarm management

Using a sophisticated alarm solution in your plant will help improve the reliability of your critical assets, and reduce your operational and maintenance costs. Using advanced alarm handling technologies and sophisticated logic to analyze alarm conditions, your plant can detect problems before they lead to failures.

Using a rules engine is a great way to combat alarm fatigue. This solution allows operators to create alarms and rules in seconds, and gives them a reliable way to sound alarms.

There are many alarm management solutions on the market, and it’s important to find the one that is right for your plant. A reputable partner can help ensure that you get the most out of your investment.

An alarm management solution should be able to handle all alarms, preferably in a way that makes your operators happy. In addition, it should be able to display the latest alarms in a clear and concise way. A good alarm management solution will be able to notify operators about the latest events, and notify them of problems in real time.

Another feature to look for is an alarm history page. This page displays the history of your system in a way that’s easy to understand, and will help you understand what’s happened to your system over the past few days.

In addition, it should be able to detect abnormalities in the data. For example, if you have a low generator starter battery, an alarm indicating this would be useful.

The best SCADA alarm management solution should be able to detect the most important alarms, while also giving the operators the most relevant information in a concise and easy-to-read format. This will help them respond to alarms in the most effective manner.

Scalability

Whether it’s the one at the office or the one at the factory, you’ll need a scalable and sharable system of record to succeed. Luckily, there are several solutions in the industry. We’ve got over 25 years of experience in the process control business. From high-performance signal conditioning and control, to real-time monitoring and alarming, we’ve got the right tools for the job. This is a major reason why we’ve earned the respect of the industry’s best. Whether you’re looking for a data center of the future, a mobile control center, or a single server configuration, we’ve got what you’re looking for. We’re your one-stop shop for all things process control. We’re also your one-stop shop for all things process automation. Whether you’re looking for scalable solutions for the future or modernizing an existing process control and automation system, we’ve got the best solutions in the industry.

Modern vs legacy SCADA solutions

Whether you’re in manufacturing, energy, water or mining, SCADA systems are a vital tool for advanced management. They provide operators with a comprehensive view of industrial processes, so they can take immediate action and prevent unplanned downtime.

Modern SCADA systems are flexible, scalable, and mobile, meaning you can roll out advanced systems faster and with fewer moving parts. This saves you time, money, and labor. In addition, they are more secure against cyberattacks.

If you’re using a legacy SCADA system, it may have been designed decades ago, and it can’t support the latest security requirements. It’s also likely not compatible with Windows XP or other modern OSes. It may also lack many of the default features that you need to make accurate measurements.

Modern SCADA solutions can help you manage hundreds of assets without having to visit each field device. They also offer real-time data collection, which can save you both overhead costs and efficiency.

If you’re still using a legacy SCADA system, it’s time to look for a new solution. It’s likely that you’ll need a new system that’s more scalable and able to support a wider range of enterprise users. It also needs to have an advanced architecture to provide a high level of visibility for both enterprise and remote users.

Modern SCADA solutions offer a single Industrial Controller, reducing the number of moving parts and allowing you to roll out advanced systems faster. These systems also offer smart alarm management, so you can solve problems without having to perform manual on-site diagnostics. You can also add internet-enabled sensors (IoT) to equipment that’s not being measured by your legacy SCADA system, giving you access to information that you couldn’t have previously.