3D printing has been around for a while now, but it’s only recently that the technology has begun to be used in conjunction with the Internet of Things. By connecting 3D printers to the internet, manufacturers can create a network of machines that can communicate with each other and share data. This allows for greater efficiency and accuracy in production, as well as the ability to remotely monitor and control the machines.

The use of 3D printing in IoT is still in its early stages, but it has the potential to revolutionize manufacturing.

One of the key advantages of 3D printing is that it allows for the creation of custom parts and products.

This is especially valuable in the IoT space, where manufacturers often need to create unique or customized products for their customers.

In conclusion, the use of 3D printing in IoT is still in its early stages, but it has the potential to revolutionize manufacturing. Discover here what is 3d printing in IoT!

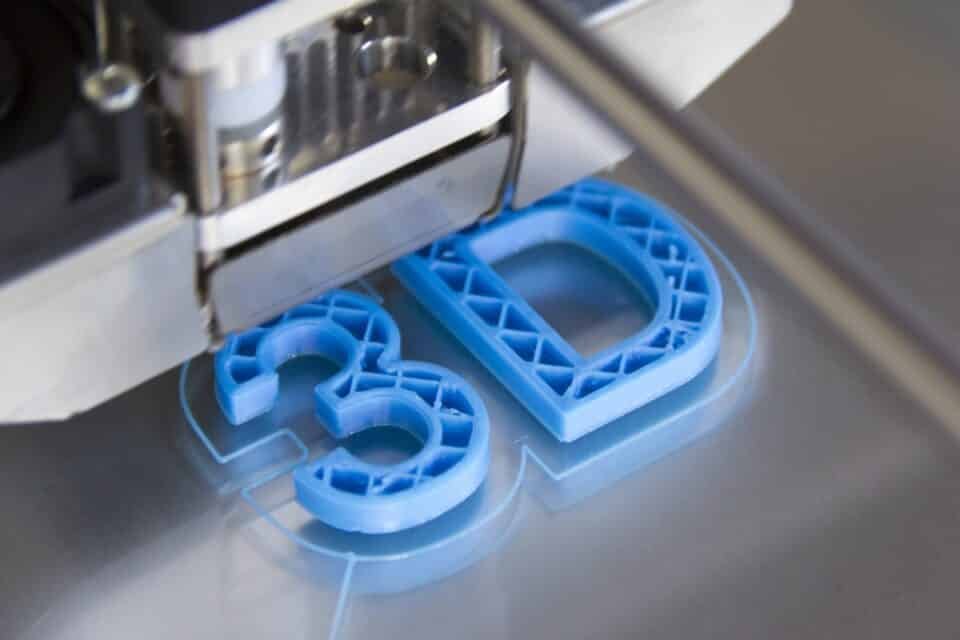

The internet of things (IoT) is a system of interconnected devices and sensors that can collect and share data. 3D printing is a process of making three-dimensional objects from a digital file. When you combine these two technologies, you get 3D printing in IoT, which is a way to create physical objects from digital designs using connected devices and sensors.

There are many potential applications for 3D printing in IoT, such as creating custom objects on demand, prototyping new products, or even printing entire buildings.

Discover the best 3D Printers. Click Here!

The possibilities are limited only by your imagination.

If you’re interested in learning more about 3D printing in IoT, read on for a brief introduction to this exciting new technology.

What is 3D printing in IoT?

3D printing in IoT is a way to create physical objects from digital designs using connected devices and sensors. This technology can be used to create custom objects on demand, prototyping new products, or even printing entire buildings.

How does 3D printing in IoT work?

3D printing in IoT works by using connected devices and sensors to collect data. You can generate a digital file that can be sent to a 3D printer. The 3D printer will then create the object from the digital file, layer by layer.

What are the benefits of 3D printing in IoT?

There are many potential benefits of 3D printing in IoT, such as the ability to create custom objects on demand, prototype new products, or even print entire buildings. This technology has the potential to revolutionize the way we manufacture goods and could have a major impact on the economy.

What are the challenges of 3D printing in IoT?

One of the main challenges of 3D printing in IoT is the need for high-quality digital files. If the file is not of high quality, the object will not be printed correctly. Another challenge is the cost of 3D printers and the need for trained personnel to operate them.

Despite these challenges, 3D printing in IoT is a promising new technology with many potential applications. As the technology continues to develop, we are likely to see even more amazing and innovative uses for it.

How 3D Printing is Transforming IoT?

3D printing has been around for a while, but it’s only recently that the technology has begun to be used in larger scale manufacturing. One of the most promising applications of 3D printing is in the area of IoT, or the Internet of Things.

IoT refers to the growing network of physical objects that are connected to the internet. These objects can communicate with each other and share data.

Discover the best 3D Printers. Click Here!

3D printing is beginning to play a role in IoT by helping to create custom-made parts for devices.

By using 3D printing, manufacturers can create parts that are specifically designed for a particular device or application. This allows for a much higher degree of customization and flexibility in the manufacturing process.

3D printing is also beginning to be used in the development of smart devices. Smart devices are devices that are connected to the internet and can collect,process, and transmit data. 3D printing can be used to create custom-made enclosures for these devices. This allows for a higher degree of customization and allows manufacturers to create devices that are specifically designed for a particular application.

3D printing is beginning to transform the way that IoT devices are made. By allowing for more customization and flexibility in the manufacturing process, 3D printing is helping to create better, more innovative devices. In the future, 3D printing is likely to play an even bigger role in the development of IoT devices.

How 3D Printing is Enabling New Possibilities in IoT?

3D printing is a rapidly evolving technology that is enabling new possibilities in the world of IoT. One of the most exciting applications of 3D printing is its ability to create custom parts and devices on-demand. This means that manufacturers can produce small batches of customized products without the need for expensive tooling or long lead times.

What are the best university courses to master 3d printing?

Another advantage of 3D printing is that it enables manufacturers to create products with complex geometries that would be impossible to produce using traditional manufacturing methods.

This opens up new possibilities for product design and allows companies to create unique devices that are tailored to specific applications.

One example of a company that is using 3D printing to enable new possibilities in IoT is IoT Worlds.

IoT Worlds service is being used by leading companies in a variety of industries to create everything from wearable devices to sensor nodes. 3D printing is enabling these companies to prototype and produce custom products quickly and efficiently.

The possibilities for 3D printing in IoT are endless. As the technology continues to evolve, we can expect to see even more amazing applications of this transformative technology.

Discover the best 3D Printers. Click Here!

The Benefits of 3D Printing for Internet of Things

The benefits of 3D printing for internet of things are manifold. With the advent of advanced printing technologies, it is now possible to print three-dimensional objects with great accuracy and detail. This has led to a significant increase in the popularity of 3D printing, especially among businesses that are looking for ways to create prototypes or small batches of products quickly and cheaply.

One of the key benefits of 3D printing for internet of things is that it offers a high degree of flexibility. Businesses can use 3D printing to create prototypes of new products or to test out different designs before committing to mass production. This means that they can save time and money by making changes early on in the design process, rather than having to make costly and time-consuming changes later down the line.

Another benefit of 3D printing for internet of things is that it can be used to create customised products. This is especially useful for businesses that need to create unique items or that want to offer personalised gifts. With 3D printing, businesses can create products that are exactly what their customers want, rather than having to settle for mass-produced items that may not be quite right.

Finally, 3D printing is also environmentally friendly.

Unlike traditional manufacturing processes, 3D printing doesn’t produce any waste products.

This means that businesses can reduce their environmental impact while still being able to produce high-quality products.

Overall, the benefits of 3D printing for internet of things are numerous and varied. This versatile technology can save businesses time and money, while also providing them with the ability to create customised and environmentally friendly products. With so many advantages, it’s no wonder that 3D printing is becoming increasingly popular among businesses of all sizes.

The Future of 3D Printing and IoT

The future of 3D printing is looking very bright. With the advent of new technologies, it is becoming increasingly easier and more affordable for individuals and businesses to produce high-quality 3D prints. In addition, the range of materials that can be used for 3D printing is constantly expanding, making it possible to create ever more complex and intricate designs.

One of the most exciting aspects of 3D printing is its potential to change the way we manufacture products.

In traditional manufacturing, products are generally created through a process of molding or machining, which can be quite wasteful and expensive. With 3D printing, however, it is possible to create products using only the amount of material that is necessary, and without any wastage. This could potentially lead to a huge reduction in the cost of manufacturing products, as well as a significant decrease in environmental impact.

Another area where 3D printing is likely to have a major impact is the field of medicine. Already, there are a number of companies working on developing 3D-printed organs and tissues. In the future, it is possible that we will be able to print entire organs from scratch, which would be a huge breakthrough for transplant medicine. In addition, 3D printing could also be used to create custom-made prosthetics and implants, which would fit patients perfectly and provide them with a much higher quality of life.

The possibilities for 3D printing are virtually endless, and it is likely that we will see even more amazing applications for this technology in the years to come.

With its ability to revolutionize manufacturing, medicine, and a wide range of other industries, 3D printing is sure to have a major impact on the world as we know it.

The Impact of 3D Printing on the IoT Industry

Though 3D printing technology has been in development since the 1980s, it has only begun to have a significant impact on industry in recent years. One of the most promising applications for 3D printing is in the area of the Internet of Things (IoT). The IoT is a network of physical devices, vehicles, home appliances and other objects that are connected to the internet and can collect and exchange data.

3D printing has the potential to revolutionize the way products are designed, manufactured and distributed in the IoT.

One of the key advantages of 3D printing is its ability to produce complex shapes that would be difficult or impossible to create using traditional manufacturing methods. This means that 3D printing can be used to create custom parts and products on-demand, which could be a major advantage for IoT applications.

Another advantage of 3D printing is its flexibility. Unlike traditional manufacturing methods, which are limited to certain materials and sizes, 3D printing can be used with a wide range of materials, including plastics, metals, ceramics and even food. This means that 3D printed products can be customized to the specific needs of each application.

Finally, 3D printing is also relatively fast and inexpensive.

This could be a major advantage for IoT applications, which often need to be produced quickly and in large quantities.

Overall, 3D printing could have a major impact on the IoT industry. This technology offers a number of advantages, including the ability to produce custom parts and products on-demand, flexibility in terms of materials and sizes, and relatively fast and inexpensive production. These factors could make 3D printing essential for the future development of the IoT.

Discover the best 3D Printers. Click Here!

We can say that 3D printing in IoT is a process of creating three-dimensional objects by depositing materials layer by layer under computer control. It allows you to create complex shapes and structures that would otherwise be difficult or impossible to create using traditional manufacturing methods. With the help of IoT, manufacturers can now monitor and manage their 3D printers remotely, allowing them to optimize the printing process and produce high-quality products. In addition manufacturers can produce 3d printed IoT device at scale! Are you ready?