The IoT industry encompasses hardware (chips and sensors) and software that manage and analyze data from connected devices, providing authentication, provisioning, configuration monitoring and device software management services.

Industrial-sector IoT systems allow companies to monitor equipment and assets remotely, anticipating when potential problems could occur and performing preventive maintenance to minimize downtime costs.

Security

IIoT devices present a significant security challenge to organizations. As they play important roles like operating machinery or monitoring an important location, these devices can easily become compromised to steal data or interfere with operations – or be combined into botnets used to distribute malware or launch DDoS attacks. For this reason, companies must implement an IoT security solution which identifies all managed and unmanaged devices and protects them against both known and unknown threats.

IoT security solutions can protect businesses against data loss, network intrusions, device tampering, malware and more. Unfortunately, many IoT devices were not designed with security in mind and this can leave hackers exploitable vulnerabilities that are exploitable through hacker exploits. Also these devices tend to use older operating systems and chipsets which introduce additional risks; furthermore they often go years between updates leaving these devices exposed and vulnerable.

As well as these issues, IoT devices can also be accessed physically by thieves. This is particularly relevant to industrial IoT, where devices frequently come into contact with humans – GPS trackers on vehicles could easily be stolen for “free data” or used to commit other crimes; similarly factory robots may be stolen and sold or used illicitly for other reasons.

Even with its many challenges, IoT security remains an integral component of any successful business. To achieve maximum protection during development of devices for IoT applications, security consideration should begin from day one of IoT deployment. CISOs can ensure IoT devices feature built-in security by mandating strong strategies, using secure protocols for communication, and avoiding third-party hardware or software that might be vulnerable to attack. Zero-trust models allow businesses to automatically enforce policies while also detecting and responding to new, unknown threats. Over time, adopting these strategies will help mitigate risks and protect business operations against IoT security breaches that threaten disruption. This will ensure that IoT brings benefits safely and affordably to both businesses and consumers alike. The global IoT security market can be divided up by component, deployment model, organization size, product type type, security type and industry vertical.

Connectivity

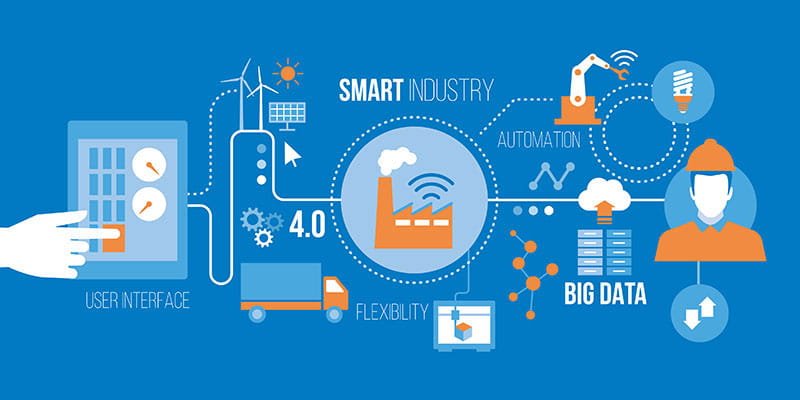

Industrial IoT (Internet of Things) is an integral component of Industry 4.0 and can be seen across industries as diverse as oil and gas, power utilities, chemicals, aerospace, automotive manufacturing and mining. But it doesn’t just stop there: Industrial IoT can also be found anywhere that requires data collection or factory monitoring or predictive maintenance services.

IoT sensors can help prevent machinery problems and alert maintenance staff when they occur, as well as enable workers to see their working environments through wearables, improving safety and productivity. Preventive maintenance has proven far more cost-efficient than reactive maintenance for saving both money and time for companies. IoT is also being used to build smart factories; sensors in machines provide data on how they’re functioning so engineers can detect issues before technicians come out for repair, ultimately increasing factory production while decreasing downtime.

Retailers are taking advantage of IoT to connect with customers and enhance the customer experience, such as building smart stores with fast payments that personalize shopping experiences for each shopper. Furthermore, these applications help retailers enforce social distancing while protecting employees while working.

Healthcare has long been at the forefront of IoT adoption and innovation. Hospitals provide ideal conditions for IoT solutions as their enormous facilities house state-of-the-art equipment, making IoT solutions especially appealing.

However, this industry faces numerous hurdles and hurdles are numerous – for instance many IoT sensors used for collecting and transmitting data are vulnerable to cyber attacks – in fact a recent report by Palo Alto Networks concluded that 98% of IoT device data wasn’t encrypted!

IoT sensors may also be vulnerable to electromagnetic interference (EMI). This is a common problem among wireless IoT technologies and can interfere with other systems, so it’s crucial that all IoT devices are shielded from EMI using either an enclosure or shielded cable, protecting data transmission while also eliminating security threats.

Discover the best course about IoT connectivity, click here.

Data Analytics

With more physical devices becoming connected to the Internet of Things (IoT), businesses require tools to collect, analyze, and evaluate this data. IoT analytics allow organizations to use massive amounts of IoT-generated information to improve products, predict equipment maintenance needs, optimize office spaces/warehouses and optimize office spaces/warehouses – this technology will become even more essential in today’s era of Big Data as more IoT devices become connected.

IoT analytics helps companies leverage their data effectively, helping them make smarter decisions and stay competitive. Furthermore, it makes processes more efficient, reliable, and productive – three essential cornerstones of any successful enterprise.

As the Internet of Things (IoT) devices generate massive amounts of data, businesses can utilize its analysis to pinpoint problems and make adjustments that address them. IoT sensors monitor an array of metrics including environmental conditions, product usage and customer behavior – providing businesses with valuable insight that allows them to tailor products and services more closely aligned to audience needs – such as tracking customers shopping behaviors for personalized recommendations.

IoT analytics can also help reduce costs by minimizing downtime and energy consumption. For instance, food vending machines can be programmed to automatically request refills when inventory levels reach certain thresholds, thus cutting maintenance costs while simultaneously increasing efficiency.

IoT analytics provide a way to track and store data from remote devices, improving medical care and supply chain logistics. For instance, sensors on IoT devices can monitor patients or products in real time to provide more accurate diagnoses and enhance treatments.

IoT analytics are having an incredible effect on many industries. Manufacturing, for instance, can use IoT analytics to increase production efficiency by identifying inefficiencies and cutting waste. Smart cities use IoT analytics to manage traffic flows more effectively while monitoring infrastructure for potential risks; eventually IoT will also help track seismic activity, natural disasters and climate change.

Discover how to create and manage a data lake, click here.

Automation

IoT (Internet of Things) technology has revolutionized industrial processes, increasing productivity and decreasing costs. Monitoring devices and equipment, gathering data to help make informed decisions by managers, notifying supervisors of issues that need attention, tracking transaction reports to spot trends over time and helping employees stay productive while away from work – this allows companies to keep production going smoothly while decreasing machine downtime caused by breakdowns.

One way that the IoT has revolutionized industrial automation is through predictive maintenance. This process uses sensors to monitor equipment and predict when it may breakdown – especially critical pieces that could impact operations negatively if their failure were to cause downtime and costly repairs. Utilizing IoT to predict equipment problems helps companies optimize maintenance schedules while saving money by avoiding expensive repairs or downtime costs.

IoT in automation can also enhance a manufacturing plant’s ability to comply with Health, Safety and Environment (HSE) standards. For instance, sensor systems equipped with IoT capabilities can monitor temperatures of refrigerated foods to ensure they remain within safe temperatures range and send alerts directly to maintenance staff if anything starts going awry, helping prevent food spoilage while protecting product integrity.

IoT technology can also assist businesses in streamlining and optimizing their supply chains and inventory management. This can reduce costs, improve customer service levels and enable more effective logistics; additionally, communication among partners and suppliers may increase efficiency and reliability; plus this technology has applications across industries including manufacturing, agriculture, energy production and transport.

IoT can be a valuable asset to any company’s toolbox, but its implementation must be done carefully to reap maximum benefit. Too often companies rush into IoT implementation without fully considering all potential risks, leading them down a path that leads to inefficiencies and extra expenses. To take full advantage of IoT solutions providers with experience in industrial automation and the Internet of Things can assist in designing systems tailored specifically for your individual business requirements and designed to scale with future expansion.

IoT Worlds teams can support you in all the phases of IoT projects, contact us today.