If you are looking for a way to make your warehouse operation more efficient, you may want to consider investing in a smart warehouses system (SWS). Smart warehouses are equipped with state-of-the-art technology that can help to automate various tasks and processes, making it easier and faster for employees to get the job done. In addition, smart warehouse can also help to improve communication and coordination between different departments, which can further boost efficiency.

If you are thinking about investing in a SWS for your business, here is a brief overview of what you need to know:

The Benefits of SWS

There are many benefits that come with investing in a SWS. Perhaps the most significant benefit is the fact that it can help to improve your warehouse operation’s efficiency. By automating various tasks and processes, you can free up your employees’ time so that they can focus on more important tasks. In addition, SWS can also help to improve communication and coordination between different departments, which can further boost efficiency.

Another benefit of SWS is that they can help to improve your bottom line. By streamlining your warehouse operation and making it more efficient, you can save money on labor costs. In addition, SWS can also help to reduce inventory levels and improve turnover rates, both of which can lead to significant cost savings.

Finally, SWS can also help to improve customer satisfaction. By ensuring that orders are fulfilled accurately and promptly, you can keep your customers happy and coming back for more.

The Disadvantages of SWS

Like any investment, there are also some risks associated with investing in a SWS. One of the biggest risks is that the technology may become outdated quickly, which could leave you with a large investment that is no longer useful. In addition, SWS can also be expensive to set up and maintain, so you will need to carefully consider whether or not the benefits outweigh the costs.

Another potential disadvantage of SWS is that they can lead to job losses. If your warehouse is fully automated, you may no longer need as many employees to operate it. This could lead to layoffs and unemployment, which could have a negative impact on your community.

Finally, SWS can also pose a security risk. If the system is not properly secured, hackers could gain access to sensitive information, such as your customers’ credit card numbers and addresses.

Making the Decision

As you can see, there are both advantages and disadvantages to investing in a SWS. Carefully consider all of the factors involved before making a decision. If you do decide to invest in a SWS, make sure to choose a reputable advisor and supplier who can provide you with quality products and services.

Introducing smart warehousing – what is it and why is it important?

Smart warehousing is the use of advanced technologies to manage warehouse operations. This includes using sensors and RFID tags to track inventory, using robotics to automate tasks, and using data analytics to optimize operations.

Smart warehousing can improve accuracy and efficiency in warehouses, while also reducing costs. It can help businesses keep up with the increasing demands of e-commerce and meet the needs of customers who expect faster delivery times.

Smart warehousing is an important part of the supply chain and can help businesses stay competitive in today’s market. Implementing smart warehousing technologies can be a complex and costly undertaking, but the benefits can be substantial. businesses that are able to successfully implement smart warehousing will be well-positioned to meet the demands of the future.

The rise of automated systems in smart warehouses

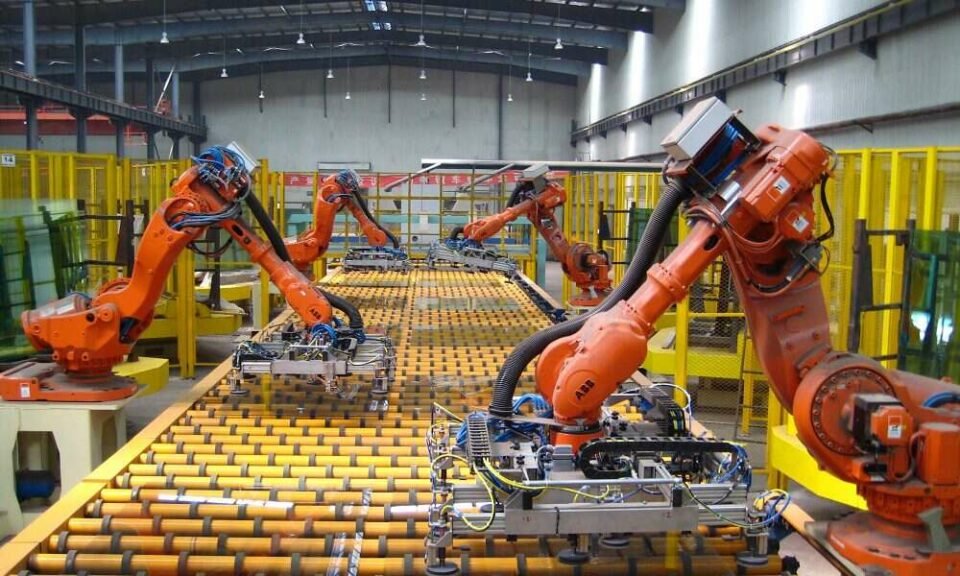

The modern business landscape is becoming increasingly complex and competitive. In order to stay ahead, companies are turning to advanced technologies such as artificial intelligence (AI) and robotics to automate their operations. One area that has seen a recent surge in adoption of these technologies is warehouse management.

In particular, the use of robots has been on the rise in warehouses as companies look to automate their material handling processes. These robots are designed to move inventory around the warehouse, which can help to improve efficiency and accuracy while reducing labor costs. These robots can be very good friends for inventory managers.

However, there are still some challenges associated with the adoption of these technologies. For example, robots need to be carefully integrated into the existing warehouse infrastructure in order to avoid disruptions. Additionally, the full cost of these systems can be prohibitive for some companies.

Despite these challenges, the use of automated systems in warehouses is expected to continue to grow in the coming years as companies look for ways to improve their operations.

How intelligent systems are changing the way warehouses operate

The deployment of artificial intelligence (AI) within warehouses is changing the way these facilities are being operated. With advances in machine learning, warehouses are able to utilize robots for a variety of tasks such as order picking, restocking shelves, and even cleaning floors. In addition, AI can be used to monitor inventory levels and predict when stock needs to be replenished. By automating these tasks, warehouses are able to improve their efficiency and accuracy while also reducing labor costs.

One of the most significant changes that AI has brought to warehouses is the introduction of autonomous warehouse robots. These robots are able to navigate through the facility without the need for human guidance and can be programmed to perform a variety of tasks. For example, order-picking robots can retrieve items from shelves and load them onto conveyor belts for transport to packing stations. These robots can also be equipped with sensors that allow them to detect when shelves are empty or items are out of stock.

Another way that AI is changing warehouses is through the use of predictive analytics. By analyzing data from past orders, warehouses can use AI to predict customer demand and adjust their inventory levels accordingly. This helps to ensure that shelves are never empty and that customers always have the items they need. In addition, predictive analytics can also be used to identify trends in customer behavior. This information can then be used to improve the overall efficiency of the warehouse.

Overall, AI is changing the way warehouses operate. By automating tasks and using predictive analytics, warehouses are able to improve their efficiency and accuracy. This in turn leads to cost savings for businesses and a better experience for customers.

The benefits of smart warehousing for businesses and consumers

The smart warehousing industry is still in its early developmental stages. However, there are already a number of benefits that businesses and consumers can take advantage of by using this technology.

Some of the main benefits of smart warehousing include:

1. Increased Efficiency

Smart warehousing systems help to streamline and optimize warehouse operations. This leads to increased efficiency and productivity, and ultimately results in cost savings for businesses.

2. Improved Customer Service

Smart warehouses can help businesses to better manage their inventory and fulfill orders more quickly and accurately. This results in improved customer service and satisfaction levels.

3. Greater flexibility

The use of smart technology within warehouse operations provides greater flexibility and adaptability. This is especially beneficial for businesses that experience seasonal peaks and troughs in demand.

4. Reduced environmental impact

Warehouses are often large energy consumers. However, smart warehouse technology can help to reduce energy consumption and the overall environmental impact of warehouse operations.

5. Enhanced security

Smart warehouses make use of advanced security systems that can help to prevent theft and other security threats.

The benefits of smart warehousing are numerous and varied. As the technology continues to develop, it is likely that even more benefits will be realized by businesses and consumers alike.

The challenges of implementing smart warehousing solutions

Smart warehousing solutions have the potential to revolutionize the way businesses operate. By automating and optimizing processes, they can increase efficiency and productivity while reducing costs. But implementing these solutions can be challenging, as they require significant investment and coordination across multiple departments.

In order to successfully implement smart warehousing solutions, businesses need to carefully consider their needs and objectives. They also need to have a clear understanding of the technology involved and how it can be used to improve their operations. Furthermore, businesses need to ensure that all stakeholders are on board with the project and that there is adequate funding in place.

Smart warehousing solutions can offer many benefits, but only if they are implemented correctly. By taking the time to carefully planning and coordinating their efforts, businesses can ensure that they get the most out of these solutions.

The future of smart warehousing – where do we go from here?

The future of smart warehousing looks very promising. From what we can see, the possibilities are endless. In the coming years, we will continue to see more and more warehouses being built with smart technology in mind. This means that they will be able to keep up with the ever-changing demands of the market and provide their customers with the best possible experience.

We can expect to see more and more warehouses using robotics and automation to help with the day-to-day tasks. This will help to improve efficiency and accuracy, as well as reducing the need for human labor. In addition, we will continue to see an increase in the use of data analytics. This will allow warehouse managers to make better decisions about inventory levels, stock rotation, and much more.

Overall, the future of smart warehousing looks very bright. We can expect to see more and more warehouses using advanced technology to improve their operations and provide their customers with a better experience.

Why smart warehousing is the way of the future?

There are many reasons why smart warehousing is the way of the future. Perhaps the most important reason is that it simply makes good business sense. A well-run warehouse operation can be a lean, mean, profit-generating machine. But in order to achieve this level of efficiency, you need to have a system in place that can provide you with real-time data and analytics. This is where smart warehousing comes in.

Smart warehousing uses a variety of sensors and tracking devices to collect data on every aspect of the operation, from inventory levels to package movement. This data is then fed into a central system where it can be analyzed to help improve efficiency and optimize operations. In other words, smart warehousing helps you to run your operation like a well-oiled machine.

There are many other benefits of smart warehousing as well. For instance, it can help to improve customer satisfaction by ensuring that orders are fulfilled accurately and on time. It can also help to reduce costs by reducing the need for manual labor and increasing the accuracy of inventory levels.

In short, smart warehousing is the way of the future because it simply makes good business sense. It can help you to improve efficiency, optimize operations, and reduce costs. If you’re not already using asmart warehousing system, now is the time to make the switch.

What is an inventory management system?

An inventory management system (IMS) is a computer software used in manufacturing and logistics to control the ordering, storage, movement and assembly of components and finished products.

An inventory management system (IMS) helps companies keep track of the goods they have in stock. It can be used to track both raw materials and finished products. An inventory management system can be used to monitor inventory levels, track stock movements, and generate reports.

An inventory management (IMS) can be a stand-alone system or it can be integrated with other business systems such as enterprise resource planning (ERP) and customer relationship management (CRM) systems.

Some of the benefits of using an IMS include:

Improved inventory accuracy

An IMS can help companies keep track of their inventory, ensuring that they have the right products in stock and reducing the risk of overstocking or understocking.

Reduced costs

An IMS can help companies save money by reducing the need for manual inventory counts, minimizing stock-outs, and reducing the amount of time spent searching for products.

Improved customer service

An IMS can help companies improve their customer service by ensuring that they have the products their customers need in stock and providing them with up-to-date information on product availability.

Increased sales

An IMS can help companies increase sales by making it easy for customers to find the products they need and providing them with up-to-date information on product availability.

Improved decision making

An IMS can help companies make better decisions by providing managers with accurate and up-to-date information on inventory levels and stock movements.

There are a number of different types of inventory management systems available, including:

1. Fixed-bin systems

Fixed-bin systems are used to track inventory in a specific location, such as a warehouse or storeroom. Each bin is assigned a unique identifier, and the system tracks the movement of inventory into and out of each bin.

2. Cycle counting

Cycle counting is a method of inventory management in which a company counts a subset of its inventory on a regular basis. This helps to ensure that the company’s inventory records are accurate and up-to-date.

3. Kanban

Kanban is a type of inventory management system that uses cards to signal the need for more inventory. The system is often used in manufacturing environments.

4. Just-in-time (JIT)

Just-in-time inventory management is a system in which inventory is only ordered and delivered as needed, in order to minimize the amount of inventory on hand.

5. Economic order quantity (EOQ)

Economic order quantity is a method of determining the optimum time to order inventory, in order to minimize the cost of holding inventory.

6. Vendor-managed inventory (VMI)

In a vendor-managed inventory system, the supplier is responsible for managing the inventory at the customer’s site. This type of system is often used in cases where it is difficult for the customer to track their own inventory levels.

How to build an IoT based inventory management solution for warehouse management?

There are many factors to consider when building an IoT based inventory management system for warehouse management. It is important to consider the needs of your business before to install an inventory management software and what type of data you need to collect in order to make informed decisions about to manage inventory through your iot inventory management solution. Additionally, you must also account for the scalability of your system as your business grows together with the warehouse management activities. Here are a few tips to help you get started:

1. Define Your Business Needs

The first step is to clearly define the needs of your business. What type of data do you need to collect about your inventory? How will this data be used? Answering these questions will help you determine the types of sensors and other devices you will need to include in your system.

2. Select the Right Hardware

Once you know what type of data you need to collect, you can select the hardware that is best suited for your needs. There are a variety of sensors and other devices available on the market, so it is important to select the ones that will work best for your business. Consider the size of your inventory and the type of data you need to collect when making your selection.

3. Implement a Scalable Solution

As your business grows, it is important to implement a scalable solution that can grow with you. account for future growth when designing your system. This will ensure that you do not have to reinvest in new hardware as your business expands.

4. Collect and Analyze Data

Data is the key to making informed decisions about your inventory. Be sure to collect data about your inventory levels, sales, and other factors that will impact your business. This data can then be analyzed to help you make decisions about ordering, stocking, and other aspects of your IoT inventory management.

5. Make Adjustments as Needed

As your business grows and changes, you may need to make adjustments to your inventory management system. Be sure to review your inventory data regularly and make changes as needed. This will ensure that your system always meets the needs of your business.

Following these tips will help you build an effective IoT smart inventory management system with a great inventory optimization and enhanced inventory tracking for your business. Be sure to tailor the system to meet the specific needs of your business in order to get the most benefit from it.

How to optimize supply chain management with IoT devices?

The Internet of Things has the potential to change the way businesses manage their supply chains. By connecting devices and assets to the internet, businesses can gather data about every aspect of their operations in real-time. This data can be used to optimize processes and make better decisions about how to manage resources.

There are a number of ways that businesses can use IoT devices to optimize their supply chains. One is by using sensors to track the location of assets and inventory in real-time in supply chains. This information can be used to plan routes more efficiently and reduce the amount of time that goods spend in transit. Additionally, IoT devices can be used to monitor the condition of goods as they move through the supply chain with IoT sensors. This data from IoT sensors can be used to identify potential problems and take corrective action before goods are damaged or lost.

Another way that IoT technology can be used to optimize the supply chain management is by using predictive analytics. By analyzing historical data, businesses can use IoT technology to predict future demand and plan accordingly. This information can help businesses avoid stock shortages and ensure that they have the right products in the right place at the right time. Additionally, predictive analytics can be used to forecast maintenance needs and schedule repairs before equipment breaks down using operational equipment data.

IoT technology can also be used to improve communication and collaboration throughout the supply chain. By connecting devices and systems, businesses can create a network that allows for real-time data sharing. This information can be used to coordinate deliveries, track shipments, and resolve issues quickly. Additionally, IoT systems can be used to create virtual warehouses that allow businesses to share inventory and resources.

The potential for IoT to optimize the supply chain is vast. By using IoT, businesses can improve efficiency, communication, and collaboration throughout their operations. Additionally, IoT can help businesses reduce costs, improve customer service, and make better decisions about their resources.

Smart warehouse management in the Internet of Things era

The Internet of Things era has seen a dramatic increase in the number of warehouses and the amount of inventory that they hold. In order to keep track of all this inventory, warehouse managers need to be able to rely on efficient warehouse management systems.

One such system is the Warehouse Information System (WIS), which uses RFID tags to track inventory levels and location. This system allows managers to see exactly where each item is located in the warehouse, and how many of each item are in stock.

Another popular system is the Warehouse Management System (WMS), which uses barcodes to track inventory levels and location. This system is similar to the WIS, but it uses a different method to track inventory.

Both of these systems are essential for efficient warehouse management in the Internet of Things era. By using these systems, warehouse managers can keep track of their inventory levels and ensure that their warehouses are running smoothly.

The future of supply chain with IoT devices

The future of supply chain is with IoT devices.

IoT devices have been around for a while now, and its potential in the supply chain industry is simply immense. By connecting devices and machines to the internet, it allows for real time monitoring and real time tracking of inventory levels, movement of goods, and much more. This level of transparency and efficiency is something that has never been possible before, and it is completely revolutionizing the way businesses operate.

There are many different applications for IoT devices in the supply chain industry, and the possibilities are endless. Some of the most popular applications include:

– Automated Inventory Real Time Tracking

By attaching RFID tags or sensors to products, businesses can automatically track inventory levels in real-time. This eliminates the need for manual inventory management system, which can be time-consuming and error-prone. The AIT can be considered an IoT devices based inventory management.

– Asset Tracking

By attaching GPS tracking devices to assets such as trucks or containers, businesses can know exactly where their assets are at all times. This allows for better fleet management and can help to prevent loss or theft.

– Temperature Monitoring

By attaching sensors to products, businesses can monitor the temperature of goods throughout the supply chain. This is especially important for perishable goods, as it can help to ensure that they stay within the proper temperature range and do not spoil.

IoT devices are changing the way businesses operate and is revolutionizing the supply chain industry. There are endless possibilities for what can be done with IoT devices in the supply chain, and the sky is the limit. Businesses that adopt IoT devices into their operations will be able to gain a major competitive advantage over those that do not.

What do you think about the future of supply chain with IoT devices? Contact us!

There are many benefits to implementing a smart warehouse system. Perhaps the most obvious benefit is an increase in efficiency and productivity. With real-time data tracking and automated tasks with IoT, your team can work faster and more accurately. This can lead to significant cost savings over time.

In addition, a smart warehouse can help you improve your customer service and satisfaction levels. With real-time tracking of inventory levels, you can avoid stockouts and backorders. This leads to happier customers who are more likely to do business with you again in the future.

Overall, a smart warehouse system is a great way to improve your business operations. With increased efficiency and accuracy, you can save money and improve your customer service levels. If you’re looking to take your business to the next level, a smart warehouse is a great place to start.

Do you have a smart warehouse? What benefits have you seen so far? Share your experiences with us!