Sempre più spesso si sente parlare di Industria 4.0, IoT (Internet of Things) e Big Data. Definizioni queste che si affermeranno sempre più nel futuro prossimo. Scopriamo insieme di cosa si tratta e come questi 3 settori rappresentino l’evoluzione, non solo dell’industria, ma anche della quotidianità.

L’industria 4.0 si basa su sistemi informatici che interagiscono con i macchinari dell’azienda, vantando capacità comunicative, di controllo e computazionali. Si può parlare di Industria 4.0 quando le aziende sfruttano strumenti afferenti al mondo dell’Internet of Things (IoT) e dei Big Data. Si tratta di tecnologie assolutamente innovative e all’avanguardia, in grado di implementare e migliorare ogni modello di business. Vediamo nel dettaglio come queste aree interagiscono tra loro.

IoT e Big Data: due tecnologie abilitanti per l’Industria 4.0

Non esiste Industria 4.0 senza le relative tecnologie abilitanti principali: l’Internet of Things e i Big Data. Tipici esempi di oggetti intelligenti sono tutti i dispositivi in grado di carpire e archiviare informazioni circa l’ambiente fisico, favorendo la loro comunicazione in rete. A oggi ormai qualsiasi oggetto può essere dotato di questi dispositivi smart volti a raccogliere ed elaborare informazioni utili circa l’ambiente in cui sono presenti. Grazie allo sviluppo e alla disponibilità di reti wireless ad alta capacità, inoltre, configurare e ricevere output circa l’ambiente circostante è possibile per tutti. Non si tratta di una tecnologia rivolta esclusivamente al mondo industriale, ma è estesa anche alla quotidianità di tutti noi. Basti pensare a tutti gli smart device che ci accompagnano tutti i giorni, dal cellulare al tablet agli oggetti wearable. Questi dispositivi possono generare e raccogliere dati, trasmetterli in rete e ricevere input anche da remoto. La mission dell’IoT è, dunque, collegare tra loro dispositivi fisici e tecnologici, consentendo all’uomo di interagire con essi sia a breve sia a lunga distanza.

A seguito del sempre più largo impiego di oggetti smart IoT, la disponibilità di dati grezzi da essi generati è in continuo ed esponenziale aumento. Si tratta dei cosiddetti Big Data. Se da un lato una tale mole di dati disponibili, rappresenta certamente un grande opportunità da sfruttare, dall’altro lato è assolutamente necessario comprendere come gestirli, integrarli e utilizzarli. Ecco che la Big Data Analysis diventa il mezzo principale per sfruttare al meglio i dati raccolti.

Il processo circolare dell’ Industria 4.0

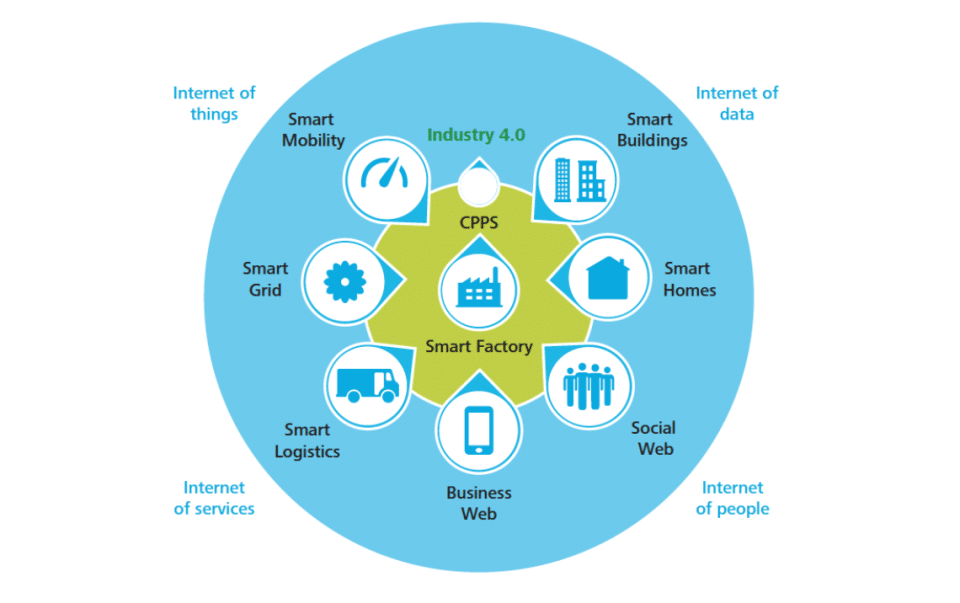

L’interazione tra oggetti, persone, servizi e dati è perpetua e rappresenta un pilastro fondamentale dell’Industria 4.0. Mediante tale interazione si ha un processo circolare continuo costituito da 3 step principali: produzione dei dati, analisi degli stessi, manutenzione e riconfigurazione dei processi di produzione. L’immagine di copertina esemplifica in modo schematico l’ambiente dell’Industria 4.0. Come già sottolineato, gli ambiti di applicazione del processo circolare sono differenti. Lo si può impiegare per un singolo processo produttivo o per le attività di più reparti.

Vantaggi in più direzioni

L’adozione interna all’azienda di questo processo porta certamente a un miglioramento obiettivo delle performance e dell’efficienza aziendale, soprattutto a livello di integrazione verticale. Ma se si espandesse l’adozione dell’IoT e della Big Data Analysis, l’influenza positiva ricadrebbe sull’integrazione orizzontale, rappresentando un reale e ottimale vantaggio per tutta la filiera di imprese. Allargando ancora di più l’interazione, e rivolgendosi anche ai Clienti, i dati raccolti e analizzati costituirebbero il motore principale dell’evoluzione dei modelli di business aziendali ad alto valore aggiunto.

Siamo certi che possiamo supportarti per i tuoi sviluppi in ottica Industri 4.0, per maggiori dettagli contattaci!

*[Immagine da Ricerca 08/2016 – Assolombardia – Approfondimento sulle tecnologie abilitanti Industria 4.0]